© ©

Restoration, Service & Hire

Restoration, Service & Hire

|

| ||

The Continental

Amongst professional electronic organs, this is one of few true classics. The Vox Continental started life in the early 1960s. Probably the first organ created specifically for professional stage use. Certainly the first in this country & undoubtedly the best. | |||

|

Dedicated to the classic instruments designed and built by the Jennings Organ Company. Later becoming Jennings Musical Industries (JMI). For a long time they were World class leaders in professional musical equipment.

In the early '60s, working for Tom Jennings' company, I built 'Mark 1' Continentals, later moving on to Service. No-one has more experience servicing these models, or genuine AC30s etc. | |||

| This was a time when Britain led the World in music, both popular and classical. Likewise in engineering and many other fields of endeavour. It is now part of our country's faded past glory. Disastrously short-sighted policies of successive Governments have seen to that. | |||

When I started with the company these organs were built one at a time. In the same area as the valve multi-manual church console models, this space also doubled for servicing.

When I started with the company these organs were built one at a time. In the same area as the valve multi-manual church console models, this space also doubled for servicing.

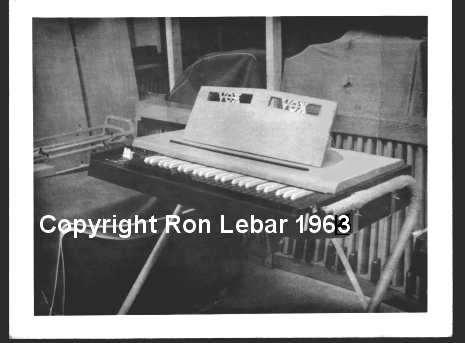

This picture is one for the archives. It is the first slimline top VOX Continental, hand built by Ron Lebar in 1963.

This picture is one for the archives. It is the first slimline top VOX Continental, hand built by Ron Lebar in 1963.

These two dual manual Continentals arrived at our Mercia workshop for service. Both need a lot of T.L.C. The left one is a Continental II, germanium all discrete circuitry, switched drawbars, no percussion. British built, like the original, but the keyboard is the "Kimber Allen" Italian SKA type, all plastic keys. It has a Jennings Organ Company name plate.

The other is an EME Italian built model 300, unfortunately minus its name plate. Steel shafted plastic shell keys, slide-pot drawbars and integrated circuit dividers. Not much resemblance to the English models, apart from the general case shape.

These two dual manual Continentals arrived at our Mercia workshop for service. Both need a lot of T.L.C. The left one is a Continental II, germanium all discrete circuitry, switched drawbars, no percussion. British built, like the original, but the keyboard is the "Kimber Allen" Italian SKA type, all plastic keys. It has a Jennings Organ Company name plate.

The other is an EME Italian built model 300, unfortunately minus its name plate. Steel shafted plastic shell keys, slide-pot drawbars and integrated circuit dividers. Not much resemblance to the English models, apart from the general case shape.

The Continental II above, with its case lid off.

A credit to Derek Underdown, its designer, now it has been serviced. I wonder, did he suspect it would still be in use, over forty years later?

The Continental II above, with its case lid off.

A credit to Derek Underdown, its designer, now it has been serviced. I wonder, did he suspect it would still be in use, over forty years later?

On the left is the EME Continental 300's interior, showing the 'rats nest' style layout. to the left of its generator boards is the open power supply, with exposed mains connections.

Italian manufacturers obviously saw no point in the, typically English, neatly laced cable-forms of the original model.

They also saw no point in the safety aspect of a mains power supply enclosed in an earthed metal case.

On the left is the EME Continental 300's interior, showing the 'rats nest' style layout. to the left of its generator boards is the open power supply, with exposed mains connections.

Italian manufacturers obviously saw no point in the, typically English, neatly laced cable-forms of the original model.

They also saw no point in the safety aspect of a mains power supply enclosed in an earthed metal case.

Continental 300H generator with faulty round can divider IC removed. Ready for replacement.

Continental 300H generator with faulty round can divider IC removed. Ready for replacement.

Same generator, fitted with socketed currently available DIL divider and interface components.

Same generator, fitted with socketed currently available DIL divider and interface components.

The Univox is a small valve monophonic organ, with a 3 octave accordian size keyboard. Designed for the same market as the Selmer Clavioline and Hammond Solovox.

It is not a copy of either of these instruments but a unique design by Les Hills, a Jennings Organ Company engineer. Intended to fit under a piano front and provide an electronic voice for the pianist.

On this J10 "Concert" model, 4 octave ranges & two sub-octave dividers are provided. Equipped with Vibrato, percussion and repeating percussion. Speed of the latter is controlled by the 3 vibrato rate tabs.

Its claim to fame in the pop music field is probably the record 'Telstar' by The Tornados. The single voice electronic sound ideally suits that tune, no-one has successfully emulated it on any other instrument.

Below are some photos of parts of this superb classic, during overhaul, the cursor will show titles.

The Univox is a small valve monophonic organ, with a 3 octave accordian size keyboard. Designed for the same market as the Selmer Clavioline and Hammond Solovox.

It is not a copy of either of these instruments but a unique design by Les Hills, a Jennings Organ Company engineer. Intended to fit under a piano front and provide an electronic voice for the pianist.

On this J10 "Concert" model, 4 octave ranges & two sub-octave dividers are provided. Equipped with Vibrato, percussion and repeating percussion. Speed of the latter is controlled by the 3 vibrato rate tabs.

Its claim to fame in the pop music field is probably the record 'Telstar' by The Tornados. The single voice electronic sound ideally suits that tune, no-one has successfully emulated it on any other instrument.

Below are some photos of parts of this superb classic, during overhaul, the cursor will show titles.